Level Flow Cascade Process Control Lab Report as PDF for free. Level Control Experiment of a Tank by Varying Both Inlet Flow and Outlet Flow as a Manipulating Variable Group.

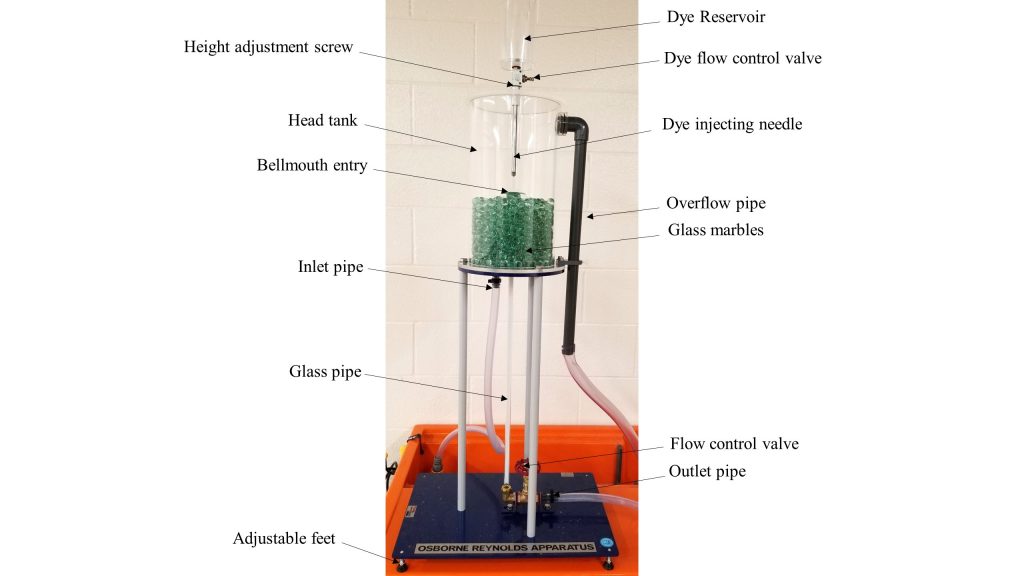

Experiment 7 Osborne Reynolds Demonstration Applied Fluid Mechanics Lab Manual

This process control laboratory is about to run open and closed loop process.

. Flow and level for data acquisition and final control elements. The students conclude that the flow process could become optimum by using the Ziegler-Nichols since the tuning rules are more practically used nowadays and based on the calculationit shows that it preferable for this level control system. Water level control is mainly used in chemicals industries.

122014 By the staff of Festo Didactic. When runnning without control the flow in valve position or both can be altered. Flow level temperature and pH control loops are available as well as various valves calibration equipment and.

Calibrated to give 0 V when the Process Vessel is empty and 10 V when at maximum level. Industrial Control and Instrumentation Engineering Stream Lab. Lab Report Manual Control - Flow Measurement Control System Page 12 Figure 1 Liquid Flow Process Control Training System 1 DDC 2 Selector 3 Control Panel FIC21 4 Pen Chart Recorder FR21 5 Annunciators 6 Test Button Green 7 Acknowledge Button Red 8 Panel SCADADDC Switch Lab Report Manual Control - Flow Measurement Control.

Simple PID Control of level and Cascade Level Control with Flow control loop are provided for each of the two processes above. Each station has a PC with. Controller by selecting high values of gain.

Abed Al-Raheem Abu Safa. An open loop. Download View Cpb30004 Process Dynamics And Control Experiment 1.

Flow Control by valve Page 2 REFERENCES. Flow control by Valve. The process control laboratory course in Chemical Engineering at Michigan Tech was recently restructured to teach students how to operate cutting edge computer-based systems and to.

Download PDF - Cpb30004 Process Dynamics And Control Experiment 1. Level Flow Cascade Process Control Lab Report d47eyv11edn2. In particular this experiment exposes the students to the fundamental modeling principle of fluid mass balance pressure sensor calibration and a feedback control design methodology for a state-coupled two-tank level.

Level Flow and Temperature Process Control. CPB30004- Process Dynamics and Control Experiment 1. This research project will only focus to control the level and flow of a process control plant.

Process Control Pressure Flow and Level Courseware Sample 86006-0. At the start of each experiment it is assumed that the level is constant at 50 and the flow in equals the flow out which is 5. Gas pressure process control lab report.

CE 117 Process Trainer Manual 1. CPB30004 Process Dynamics and Control Experiment 1 Level flow. Curriculum Coverage Flow level familiarisation calibration Interface familiarisation calibration Controller familiarisation calibration Float Level Transmitter Pulse Flow Transmitter On-Off Control Study of P PI PID Control of Level Flow Tuning PID Controllers Advanced Process Control Features.

The training systems are part of the Instrumentation and Process Control program which uses modern equipment and a complete curriculum to help students assimilate the theoretical and. In this lab the quality of the product stream green dye and water solution was analyzed using control charts X-bar for the operating process level and R for variability which were created by 1 an estimation method in JMP and 2 a standard deviation method. In this experiment five closed loop analysis are involved which comprises of Level Control Process LIC 11 Air Flow Control FIC 91 Air Pressure Control PIC 92 Flow Control FIC 21 and Liquid Flow Process FIC 31.

Level Flow and Temperature Process Control. This is done by using a PID level control system cascading into PID Flow control system at the inflow. View Process control lab reportdocx from CIVIL TECH 221-547-DW at Dawson College.

Automatic Controls Laboratory Lab 8. Level Flow Cascade Process Control 10 Page 1. CPB30004 Process Dynamics and Control Experiment 1.

First of all the designed tool menu is obtained by right clicking in the block diagram panel. The Pressure Flow Level and Temperature Process Learning Systems introduce students to a wide range of industrial processes as well as to their instruments and control devices. The outflow T31 is by gravity from the tank bottom discharge pipe.

Two types of level processes have been designed into the pilot plant namely an Integrating Process and a Self-regulating process. Stand-alone control stations are used to govern each process. Process Control Laboratory64458 Instructor.

Level is controlled via a feedwater control valve. Contains a selection of level flow. Instruction for Preparing the Laboratories Report 4 Safety Regulations 7 pH Control 8 Pressure Control 16 Flow Control 24 Temperature Control 34 Level Control 44 Distillation Control 52 Tunning 74 Dynamics of stirred tanks 81.

Example of process control that are used in industries are in municipal solid waste incinerator CSTR crystallization process maize drying process cement rotary kiln furnace etc. The conversion of degree centigrade to Fahrenheit can be done by making the block diagram with the help of adder multiplier and the control temp according to the relation 𝐹329 𝐶5 F 18 C 32 PROCEDURE. It is used in level and flow controllers.

86006-10 First Edition Revision level. By using the response curve. CPE533 Shell and Tube Heat Exchanger Full Lab Report.

The Process Vessel includes a Heat Exchanger coil. The CE117 Process Trainer. In this case it is the open loop response of the system which is given.

Lab Report Simulation Automatic Level Control System DCSFOXBORO Page 2 20 INTRODUCTION Process. The example of the process variables are temperature pressure and fluid flow rate and liquid level in the tank and other properties of materials such as density pH value viscosity. In this laboratory exercise the students model calibrate and control a two-tank level control system.

In self-regulating process the outflow rate of depends on the inflow or level of T31. It can minimize offset but cannot fully eliminate offset. Level flow cascade process control lab report - Free download as Word Doc doc docx PDF File pdf Text File txt or read online for free.

Ziegler Nichols Method An Overview Sciencedirect Topics

Elements Of Process Control Instrumentation And Control Engineering

Control Valves And Their Principles Of Operation

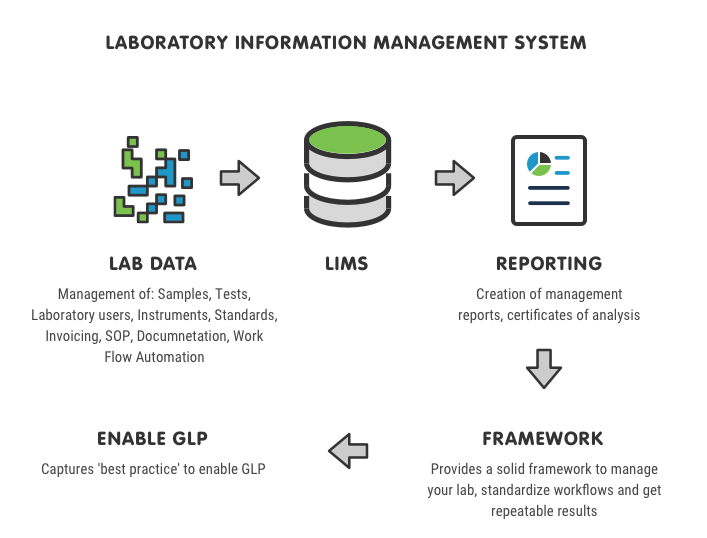

Laboratory Information System An Overview Sciencedirect Topics

On Off Controller Principle Inst Tools

What Is A Lims Lims Definition Autoscribe Informatics

Proportional Controller An Overview Sciencedirect Topics

Template Lab 40 Gap Analysis Templates Exmaples Word Excel Pdf 953eecbf Resumesample Resumefor Analysis Report Template Business Risk

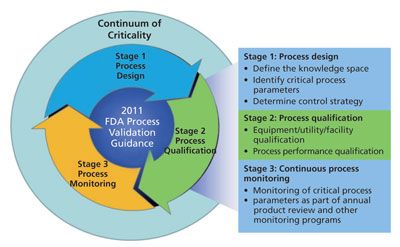

Determining Criticality Process Parameters And Quality Attributes Part I Criticality As A Continuum

Processes Free Full Text Industrial Process Monitoring In The Big Data Industry 4 0 Era From Detection To Diagnosis To Prognosis Html

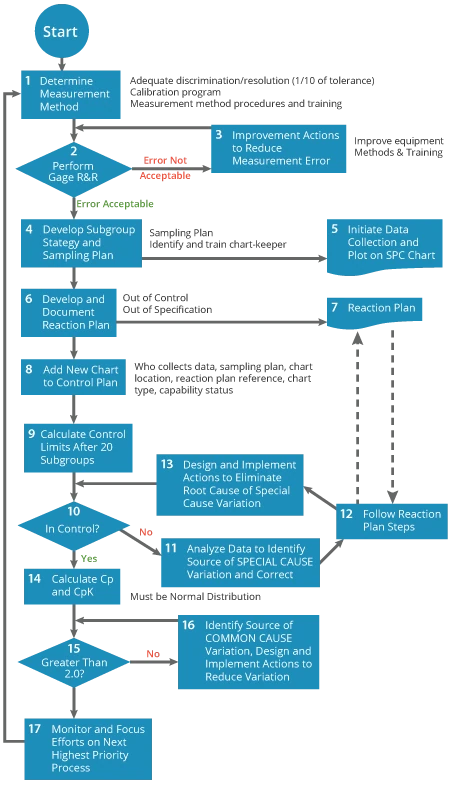

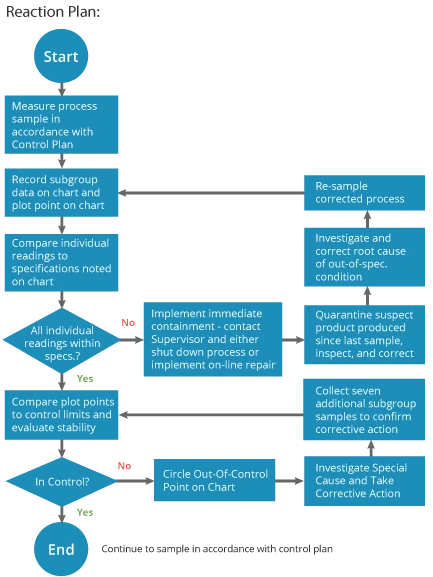

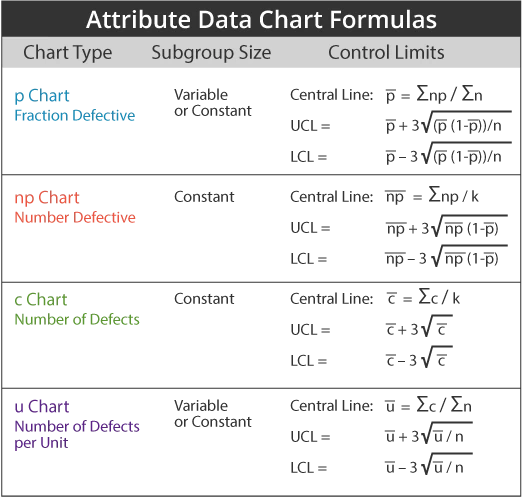

Statistical Process Control Spc Tutorial

Distributed Control System An Overview Sciencedirect Topics

Plc Program For Water Level Control Plc Level Control Ladder Logic

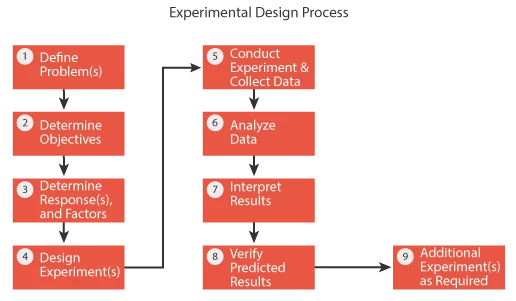

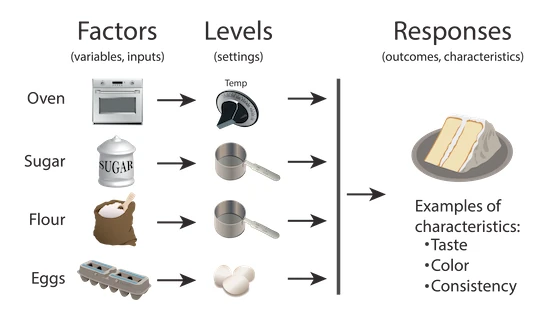

Design Of Experiments Doe Tutorial

Ppap Production Part Approval Process Quality One

Design Of Experiments Doe Tutorial

Statistical Process Control Spc Tutorial

Statistical Process Control Spc Tutorial

Chemical Reactors Quimica Ingenieria Quimica Cinetica Quimica